Concepts / Solutions

Introduction:

The Palm Oil business is an ecosystem with plantations, mills, refineries, and edible oil distribution channels.

A certain size is required to get economies of scale and a competitive CPO price.

Due to the fruit weight and humidity, plantations have to be close to mills. Plantations can be owned by mills, by small planters or by a mix of them.

Most mills have a capacity between 45 and 60 T/h (Tons of Fresh Fruit Bunches (FFB) per hour). To feed the mills, plantations between 10.000 and 20.000 hectares are required.

Carbon cycle:

In tropical countries initially covered by rain forests, soils had around 5% organic matter. Palm plantations are also a kind of forest but organic matter in soils is reducing dramatically and, as an average, is around 1,5% after 2 cycles of plantation. Why? Where is all this carbon going? To the atmosphere unfortunately. Is it good for the environment? Obviously not (greenhouse effect). Is it good for the plantation: neither (lower yields, lower resistance to drought periods and to parasitism). Is it good for the oil extraction: neither (going down).

If palm plantation is a fantastic “photosynthetic factory”, capturing CO2 from the air and transforming it into biomass, how can we make disappear the Carbon so easily? What are we doing?

Nutrients cycle:

No nutrient is exported by this agro-industrial activity. So, why do we need to fertilize annually?

All the nutrients present in the fruits (FFB), received by the mills, “disappear” in the process. Where are they going? A (very) small part is burned. Most is thrown to the rivers or dumped.

By-products (POME / EFB):

POME are nutrients-rich. They have a fertilizer value between 4 and 5 US$/T FFB (Fresh Fruit Bunches) and are an opportunity to restore the soil fertility.

EFB have less nutrients and a high C/N ratio but have nevertheless a fertilizer value around 3 US$/T FFB.

The CPO business has been so good these last decades that most of the stakeholders, only dedicated to selling their main product (CPO), have accepted to:

- Lose 7 to 8 US$/T FFB in nutrients (*).

- Lose organic matter in their soils.

- Spend money in investment and O&M for POME ETPs and EFB dumping.

taking advantage that presently the natural resources have no price and that the market does not make a difference between (good) oil and (bad) oil.

This situation is progressively changing with new market drivers (ISCC, RSPO and similar).

(*) Each 60 T/h mill, milling 300.000 T/year, is presently throwing and dumping more than 2 million US$ of nutrients and organic matter PER YEAR, while at the same time:

- Buying fertilizers for the plantation.

- Generating GHG with POME ponding and with Nitrogen fertilization.

- Struggling against consequences of the impoverishment of the soils.

- Putting in danger the sustainability of its business.

Biogas:

Biogas is a by-product of the traditional “effluent lagooning”. It is a Greenhouse Gas (CH4), and its liberation must be avoided.

Biogas capture is an opportunity to generate some financial resource from POME.

Nevertheless:

- As most of the mills are energy self-sufficient, the value of this renewable natural gas is low and is basically limited to electricity generation for the Grid through a “feed-in-tariff”. The F-I-T opportunities are limited and depends on the Grid operator and on the Governmental rules. When it is possible, the paperwork rarely justifies the time and money investment. It is an elegant way to “get rid” of the GHG but not really an attractive business unit. Main value of a biogas is COD removal at low cost on a compact area, and adequacy of the POME for its transformation into a valuable biofertilizer, opening the option of zero discharge.

- A biogas plant has the advantage to neutralize the effluent (pH 7 to 8), improve the C/N ratio and produce humic acids, so that the treated effluent is not so damageable on the environmental and could be used for plantation fertilization. But it has to be used. If it goes to existing ponds (lagoons), both [stabilized] organic matter and nutrients will be discharged to rivers (and partly evaporated to the atmosphere). The business cannot afford to do all that investment to finally throw the carbon and fertilizer content to the environment and go on with soils impoverishment.

As a conclusion, a biogas plant for methane (GHG) capture is a valuable tool but not a solution by itself to recycle organic matter and nutrients to the soils, neither to generate a profitable business except if the mill is small, not energy-sufficient and requires some fossil fuel.

Our job:

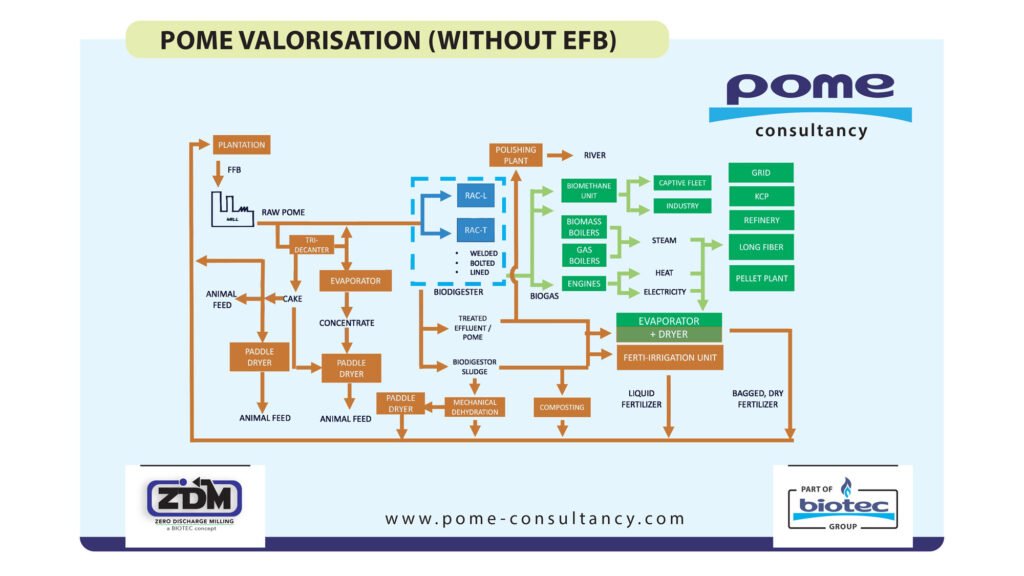

POME CONSULTANCY has a holistic view of the CPO business and considers that both POME and EFB have to be used for own plantations or sold as valuable biofertilizers, achieving Zero Discharge Milling (ZDM). Discharge to the environment is only acceptable on a short-term, but not as a business standard. Therefore, our job is to find, case by case, the best, more sustainable and more profitable uses for both by-products. Among the technologies to be evaluated, case by case, to reach the Zero Discharge Milling:

- Monitored and dosed liquid fertilization (FORLIM)

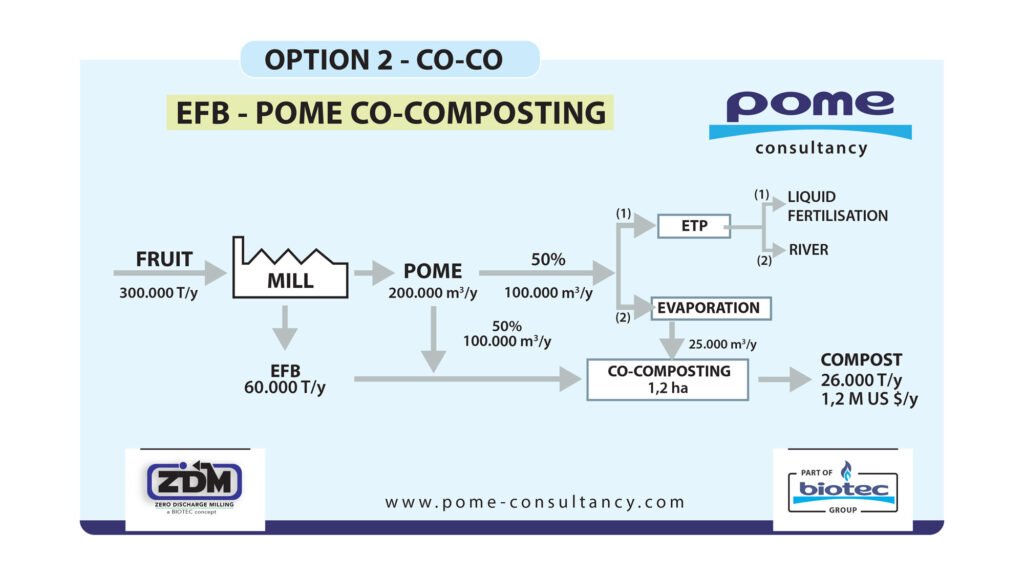

- EFB + POME co-composting

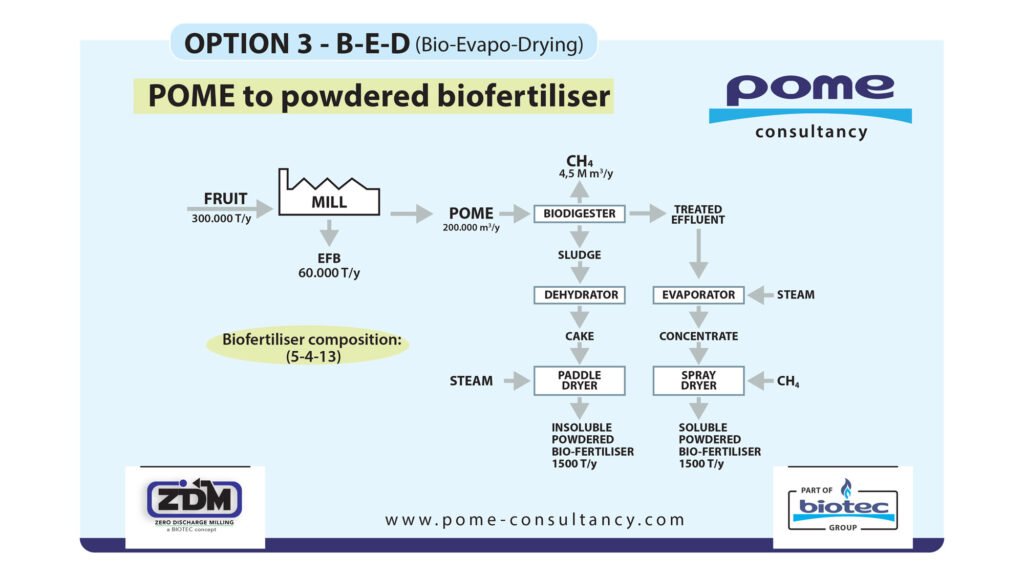

- POME to powdered biofertilizer

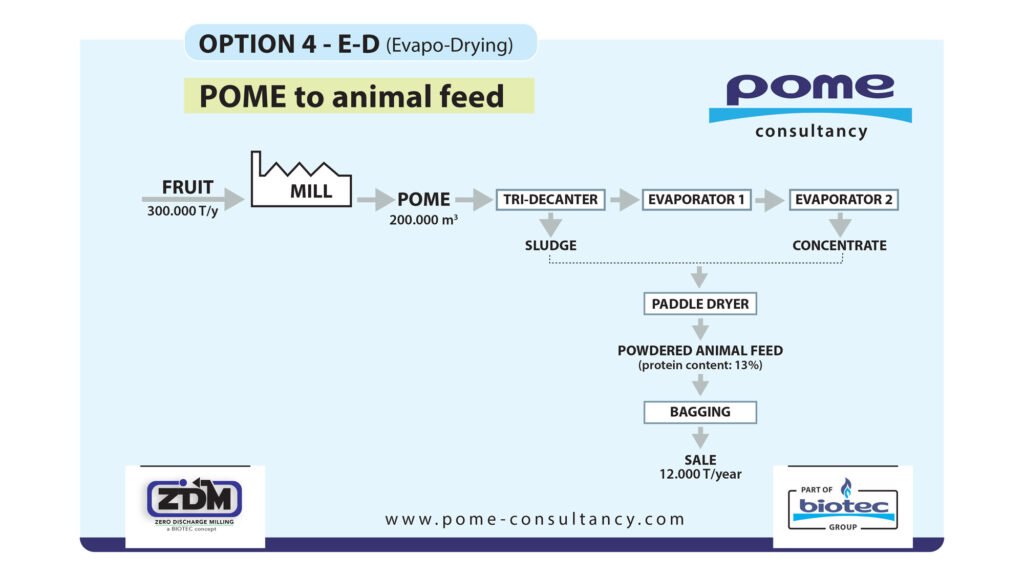

- POME to powdered animal feed