PALM OIL SUSTAINABILITY

Palm Oil Mills only export oil (carbon + oxygen + hydrogen) while plantations consume chemical fertilizers (NPK). Where is the mistake? Our agribusiness is based on biomass production (photosynthesis). Biomass productivity is excellent, but soil fertility is decreasing year after year. What are we doing wrong?

“What comes from the soil must return to it, namely: manufacturing processes must close the cycle of carbon and nutrients and not discharge it into the air or watershed.”

Tropical climate is favorable for high-yield biomass production.

S-E Asia is an example of it, with a strong, productive and diversified agriculture and agribusiness.

Organic matter (OM) in the soils improves physical, biological and chemical soil properties and is a requirement for biomass productivity and resistance to droughts and parasitism.

Due to high temperatures and humidity, organic matter has a high rate of mineralization in tropical soils; a permanent organic matter addition is therefore required.

A failure in organic matter management drives to a reduction of agricultural production and sustainability and/or to an increase in the cost of chemicals and other inputs.

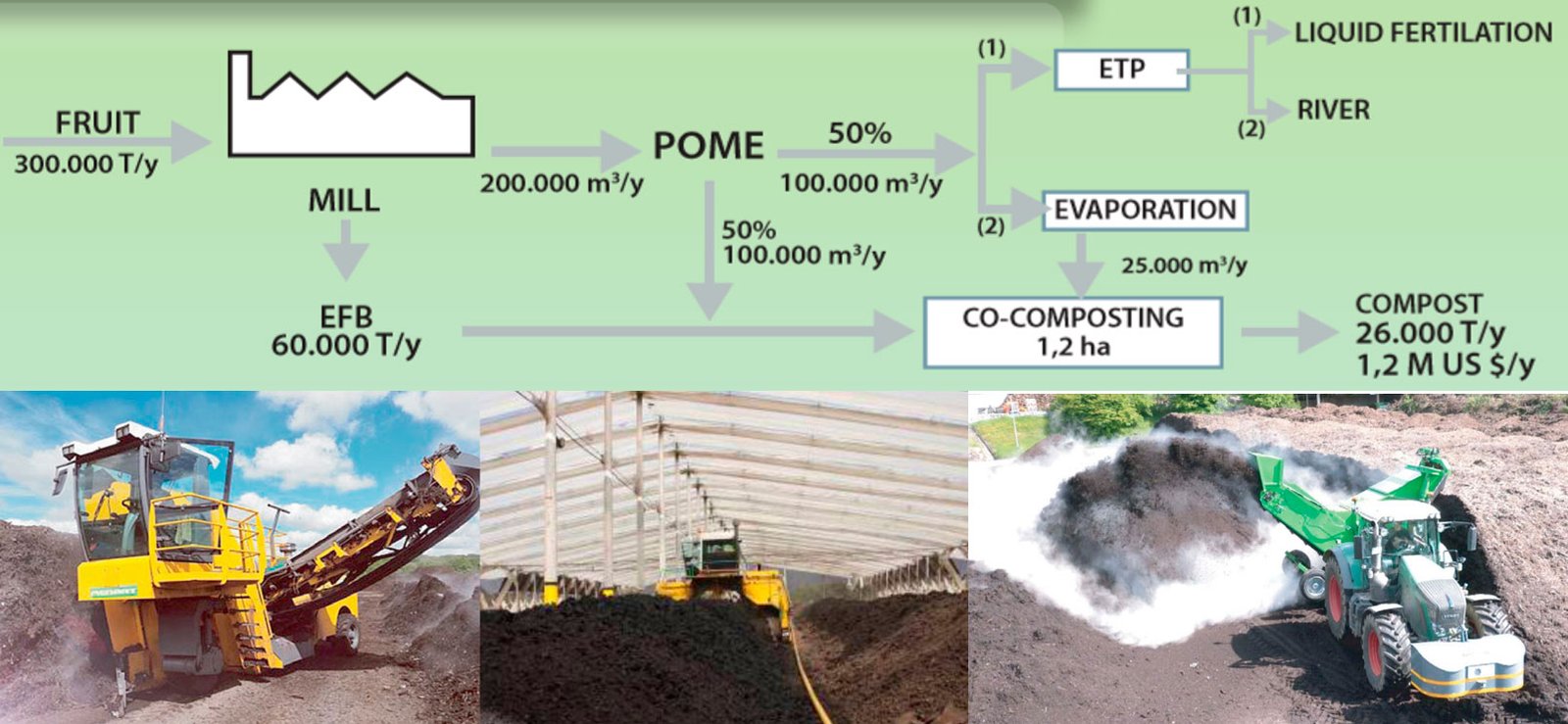

The stagnation of palm oil yields (average of 3,8 T oil/ha-year) in the last 40 years is an example of it, despite an impressive R&D and a today complete knowledge of the Elais Guinensis DNA. We can produce 6 tons CPO/ha-year, and even more, but we “stick” to 3,8 T/ha-year. Organic matter and nutrients discharge to the environment (pollution) is not a sustainable long-term option for human activities. Industries and cities have the right to use freshwater meanwhile wastewater discharge to the environment is not a permanent effect of their business. Organic load (COD, BOD) removal, with ETP (Effluents Treatment Plants), under local regulations, is an acceptable short-term answer, but not a sustainable solution.

Organic matter comes from the photosynthesis (biomass production) and must go back to the soils. Nutrients have also to go back to soils to reduce chemical fertilizer requirements. Doing it, human activities can achieve zero discharge and cero pollution, maintain the soils, avoid Greenhouse gases (GHG), assure sustainability of the businesses and generate jobs.

How to do it efficiently and profitably in the Palm Oil Industry, setting up some side-line businesses? This is “POME CONSULTANCY” expertise.

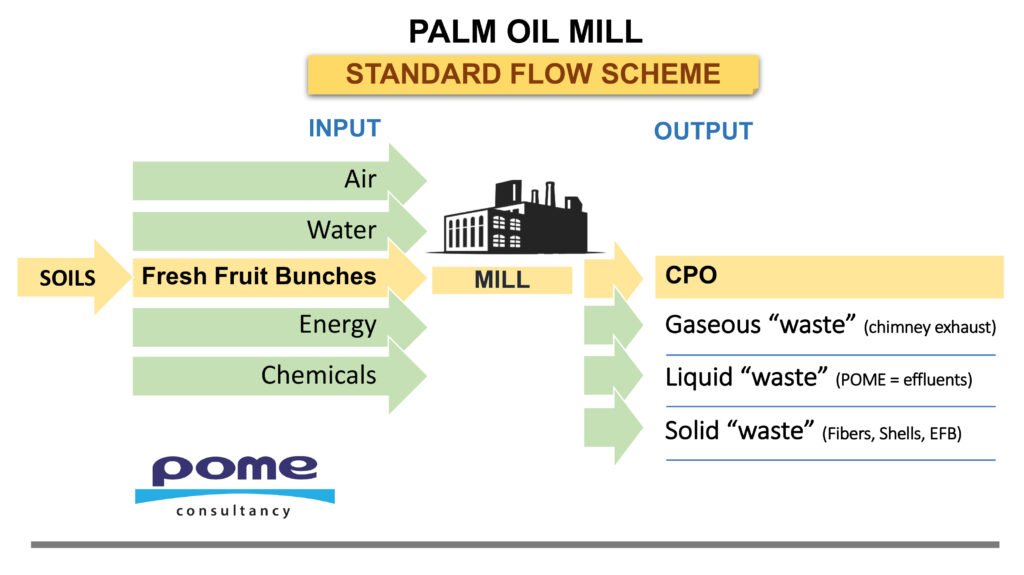

Agro-industries transform biomass into some marketable product. They need some inputs, and they generate by-products and effluents. In the palm oil sector, the marketable product (CPO) is only 22% of the weight of the Fresh Fruit Bunch (FFB), and the weight of the FFB is only part of the biomass production:

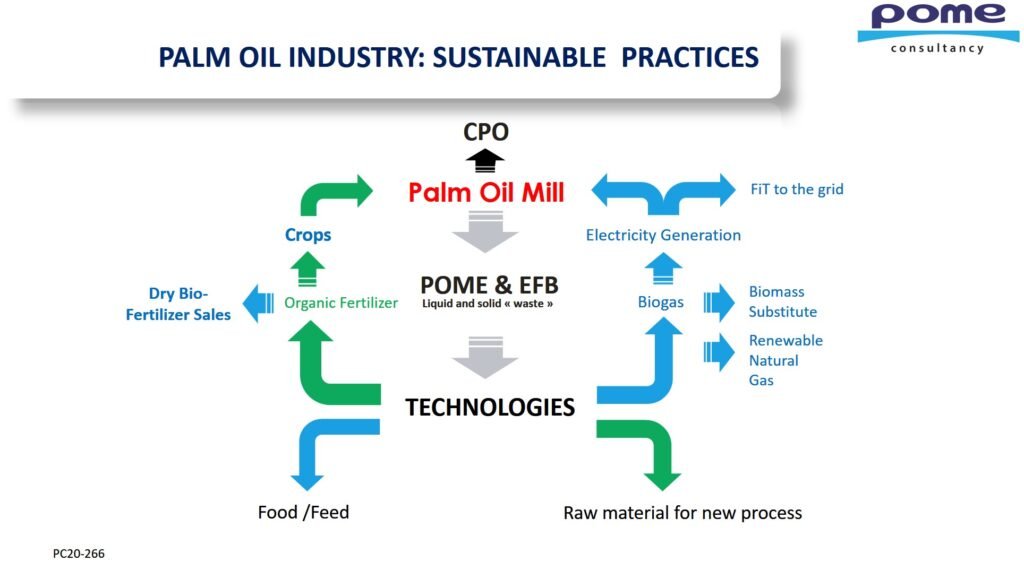

To discharge to the environment is not compulsory; it is a decision. Many options exist to avoid it and transform the ETPs cost centers into side-line businesses profit centers:

MAIN TECHNOLOGIES USED

Biogas Plants

Polishing plants

Composting plants

Evaporation

Drying

Liquid organic fertilization

Water Recirculation in industrial processes

Animal feed production